Special PCBs are customized circuit boards designed to meet unique requirements that go beyond standard PCB applications. These boards may include specific materials, designs, or manufacturing processes tailored for particular industries or use cases, such as medical devices, automotive systems, or aerospace technology. Special PCBs can incorporate features like flexible designs, high-temperature resistance, or advanced thermal management, ensuring optimal performance under demanding conditions.

These tailored solutions provide innovative and reliable electronic systems that cannot be achieved with standard PCBs, making them ideal for specialized applications that require precision and high performance.

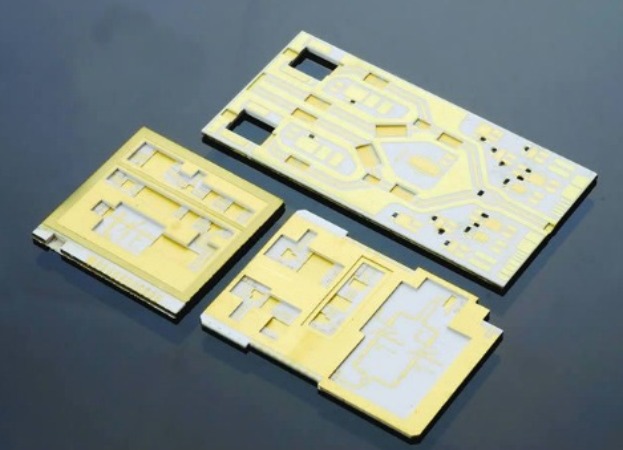

Special PCBs are customized circuit boards designed for specific, non-standard applications that require unique features and performance characteristics. These boards can be tailored with specific materials, structures, or design attributes to meet the needs of industries like aerospace, medical, automotive, and telecommunications. Special PCBs may incorporate elements like flexible circuits, high-temperature resistance, or complex multi-layer designs to ensure optimal functionality in specialized environments. By offering custom solutions, Special PCBs enable the development of advanced electronic systems that standard boards cannot support, ensuring reliability and precision for critical applications.

Shape: max. 100 mm × 100 mm

Line width / spacing: min. 0.075mm / 0.15mm

Printed conductor thickness: 10 ~ 25 μm

Printing line width accuracy: ±10 μm

Stack alignment accuracy: ≤30 μm

Through hole diameter: min. 0.1mm

Sintering shrinkage accuracy: ±0.2%

Distance between conductor and shape edge: min. 0.2mm

Distance between metal through hole and line: min. 0.15mm

Overlap distance of resistance / conductor: min. 0.15mm

Resistance size: min. 0.15mm × 0.15mm

Total number of media layers: ≤40 layers

Application: Filter PCB, diplexer PCB, LTCC chip antenna PCB

We're pleased to be welcoming customers to join us.