Electronics project development is a series of processes from product design and development to final market launch. The process includes steps such as defining development goals, establishing an integration platform, gathering technical qualifications, hardware development, software development, designing circuit schematics, checking mechanism interference, performing signal integrity simulations, and reference design.

Electronics development is usually not a smooth linear process and may require multiple iterations, depending on the complexity of the product/hardware and the technical capabilities of the team.

We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

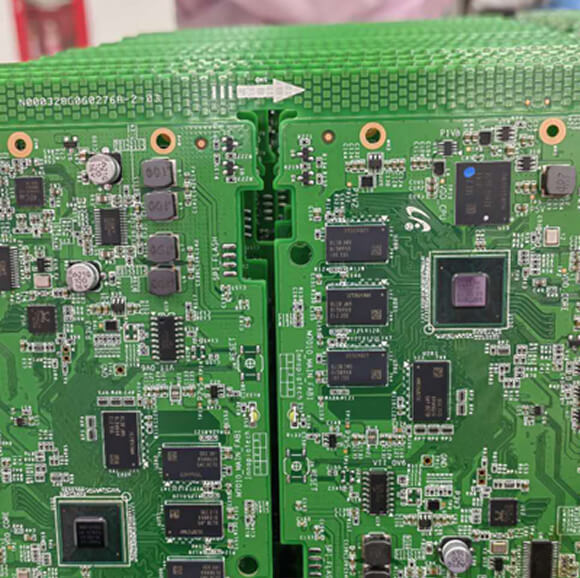

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

We have a team of designers with rich experience and excellent technology that can provide design with excellent performance, reliability, feasibility and cost benefits.

You can get a comprehensive target better design program, and can strive for product design and manual Rove Quality, shorten the product development cycle.

We prototype products within 24 hours, complete functional testing, find problems, and solve problems.

8 High-speed installation lines have stable output, which can meet all the production needs of customers.

Professional quality teams, production, testing, assembly of all-round management and control of product quality, machine detection and manual testing.

We have 4 professional finished assembly lines to quickly complete the customer’s order needs and deliver high-quality products to customers.

We're pleased to be welcoming customers to join us.