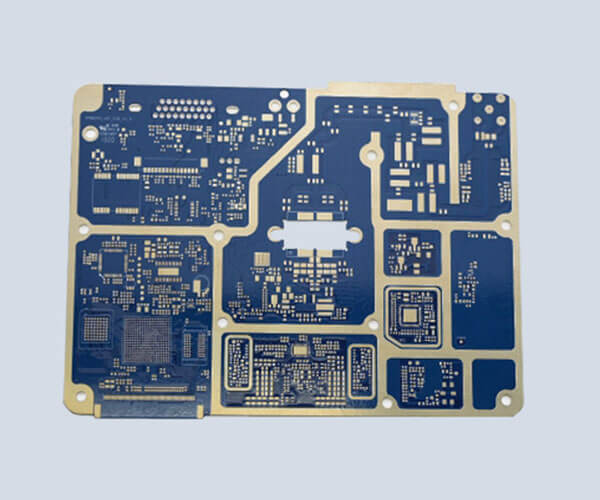

Rogers PCBs are high-performance circuit boards made from advanced materials designed to provide superior electrical properties. Known for their excellent signal integrity, low-loss characteristics, and high-frequency performance, Rogers PCBs are widely used in industries such as telecommunications, aerospace, automotive, and medical devices.

They are typically made from materials like PTFE (Polytetrafluoroethylene), which offers low dielectric constants, and their ability to perform under high-frequency conditions makes them a preferred choice for applications that require precision and reliability. Rogers PCBs support complex designs while ensuring optimal electrical performance and durability, even in harsh environments.

Rogers PCBs are high-performance circuit boards known for their exceptional electrical properties, making them ideal for high-frequency applications. Made from advanced materials like PTFE (Polytetrafluoroethylene), Rogers PCBs offer low dielectric constants and minimal signal loss, ensuring superior signal integrity and high-speed performance. These PCBs are widely used in industries such as telecommunications, aerospace, automotive, and medical devices, where precision and reliability are critical. Rogers PCBs provide excellent thermal stability and low-loss characteristics, making them suitable for demanding environments where high performance and durability are required.

Number of manufacturing layers: 1-48 layers

Number of SMT lines: 8 high-speed SMT mating lines

SMT daily production capacity: More than 50 million points

Inspection equipment: X-RAY tester, first piece tester, AOI automatic optical tester, ICT tester, BGA rework station

Mounting speed: CHIP component mounting speed (optimal conditions) 0.036S/chip

Minimum package: 0201, accuracy up to +0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be pasted, pin spacing up to +0.04mm

18 years of pcb manufacturing experience Authoritative manufacturing team

Adoption of advanced technology and manufacturing equipment Perfect production system Fast turnaround

Mature ISO9001/IATF16949 quality management system. Perfect ERP and MaS order management system.

Professional cost control engineers Cooperation with many raw material companies.

Free DFM inspection of PCB files and BOMs. PCB engineering evaluation and advice.

Specialized in medical, automotive, consumer electronics, new energy pcb. Serving global enterprises

Rogers PCB is a high frequency board produced using materials sourced only from Rogers. It uses ceramic substrate as high frequency material without glass fiber and has excellent dielectric constant and temperature stability, low loss angle tangent and high thermal conductivity. It is widely used in microwave communication, 5g, military radar and other high-frequency PCB and high-reliability fields.

① Low dielectric constant (Dk): Rogers PCB materials have a low dielectric constant, typically between 2.2 and 3.5, which means that they can maintain signal integrity and minimize signal loss at high frequencies and over long distances.

② Low loss tangent (Df): Rogers PCB materials have a low loss tangent, typically between 0.001 and 0.002, which means that they can minimize signal attenuation and distortion.

③ High thermal conductivity: Rogers PCB materials have a high thermal conductivity, typically between 0.5 and 2 W/mK, which means that they can effectively dissipate heat and maintain stable performance even at high temperatures.

④ Dimensional stability: Rogers PCB materials have a low coefficient of thermal expansion (CTE), typically between 10 and 17 ppm/°C, which means that they are less likely to warp or deform under temperature changes.

⑤ Uniform material structure: Rogers PCB materials have a uniform material structure, which means that they provide consistent performance across the board.

Rogers 3003

Rogers 3003 is a PTFE composite material with added ceramic fillers. This material gives Rogers 3003 an extremely high temperature stability of its dielectric constant. The thermal stability coefficient (Z-direction) of its dielectric constant can be as high as -3 ppm/°C when the temperature changes from -50°C to +150°C. At the same time, Rogers 3003 maintains a high dielectric constant frequency stability and can be used over a wide frequency range.

Rogers 4003C

Rogers 4003C is a high-frequency PCB material manufactured by Rogers. It has excellent electrical and mechanical properties and is widely used in high frequency circuit design and high reliability electronic equipment.

Rogers 4003C uses a special polytetrafluoroethylene (PTFE) substrate with a low dielectric constant and dielectric loss, which can effectively reduce signal transmission loss and interference. It also has high temperature resistance and mechanical strength to meet the needs of high-reliability applications.

Rogers 4350

Rogers 4350 is a high performance material for PCB signals consisting of hydrocarbon resin/ceramic filler reinforced glass fibers instead of PTFE.It offers cost savings compared to conventional microwave laminates because it does not require special THT through-hole processing. The material has a stable dielectric constant over a wide frequency range and a low temperature coefficient, making it an ideal substrate for broadband applications.

Rogers 4830

Rogers 4830 is a thermoset laminate material specifically designed for 77 GHz and 79 GHz millimeter wave radar sensors. It is based on the Rogers RO4000 series of hydrocarbon resin and ceramic filler material systems, featuring a dielectric constant that matches the low dielectric constant (Dk3.24), as well as extremely low insertion loss characteristics with the same ease of processing as the RO4000 series.

Rogers 4835T

Rogers 4835T is a high-frequency PCB material characterized by low loss, high mechanical strength, and dimensional stability. It is made of hydrocarbon resin and ceramic filler and has excellent electrical and mechanical properties.

Rogers 5880

Rogers 5880 is made of glass staple fibers filled with PTFE resin, which has a very low dielectric constant and loss factor to effectively reduce signal transmission loss and interference, and improve signal transmission speed and stability. In addition, it has high mechanical strength and excellent dimensional stability to meet the needs of high-reliability applications.

| Rogers Materials | Dielectric Constant | Other Properties |

| Rogers 3003 | 3.00 +/- .04. | Dissipation factor:0.0010 to 10 GHz |

| Substrate thickness: 0.02 “(0.5 mm) | ||

| The thickness of copper: 0.5 ounces | ||

| Low X, Y and Z axis CTE of 17, 16 and 25 ppm/°C, respectively | ||

| Rogers 4003C | 3.38 +/- 0.05 | Dissipation factor: 0.0027 at 10 GHz |

| Low Z-axis coefficient of thermal expansion at 46 ppm/°C | ||

| The volume resistance: 1.7×10&10 | ||

| Surface resistance: 4.2*10&9 | ||

| Rogers 4350 | 3.48 +/- 0.05 | Dissipation factor: 0.0037 at 10 GHz |

| Low Z-axis coefficient of thermal expansion at 32 ppm/°C | ||

| Glass transition temperature (TG) of over 280°C | ||

| Surface speed of less than 500 SFM | ||

| Chip Load less than 0.05 mm during perforation | ||

| Rogers 4830 | 3.24 | Insertion loss : 2.2 db/in at 77 GHz |

| UL 94 V-0 flame retardant rating | ||

| Dielectric thicknesses of laminates: 0.005 and 0.0094 | ||

| Rogers 4835T | 3.3 | Density 1.92gm/cm3 |

| Thermal conductivity 0.66w/m/k | ||

| Flame retardant laminate, UL 94 V-0 rated | ||

| Glass transition temperature Tg of over 280 degrees | ||

| Rogers 5880 | 2.20 +/- .02 | Dissipation factor of .0009 at 10GHz |

| Extremely low density of 1.37g/cm3 | ||

| Z-axis TCDk as low as +22ppm/°C | ||

| Isotropic |

We're pleased to be welcoming customers to join us.

Shenzhen Leadsintec Technology Co., Ltd. is a leading Rogers PCB manufacturer and supplier, delivering premium, high-frequency printed circuit boards (PCBs) for telecom, aerospace, automotive, and medical device industries. Our Rogers PCBs are engineered for low dielectric loss, high signal integrity, and exceptional thermal and mechanical stability, ensuring superior performance in critical applications.

Whether you’re sourcing PCBs for RF circuits, microwave applications, or high-speed digital designs, Leadsintec is your reliable partner for precision, consistency, and timely delivery worldwide.

As a top Rogers PCB supplier, we focus on quality, accuracy, and reliability. Here’s why companies across the globe trust us:

✔ Advanced Manufacturing Capabilities

✔ Precision & Quality Control

✔ Reliable Supply Chain

Our Rogers PCBs are made from high-quality materials such as PTFE (Polytetrafluoroethylene) and reinforced composites. Key advantages include:

These features make our Rogers PCBs ideal for applications requiring high reliability and signal integrity.

We offer a wide range of Rogers PCB materials, optimized for various high-frequency applications:

|

Model |

Features |

Applications |

|

Rogers 3003 |

Stable Dk from -50°C to +150°C |

Aerospace, automotive radar |

|

Rogers 4003C |

Low Dk & Df, mechanically stable |

High-frequency telecom, FR4 alternative |

|

Rogers 4350 |

No special through-hole processing |

Volume production, cost-effective RF PCBs |

|

Rogers 4830 |

Optimized for mmWave frequencies |

5G, advanced radar applications |

|

Rogers 4835T |

Low loss at high frequency, high thermal stability |

Multilayer RF PCBs |

|

Rogers 5880 |

Ultra-low Dk & loss tangent |

Signal integrity-critical applications |

Our Rogers PCBs are trusted in industries that demand precision, high-frequency performance, and reliability:

We not only supply locally in China but also deliver internationally. Key advantages of sourcing from us include:

When sourcing Rogers PCBs, trust Shenzhen Leadsintec Technology Co., Ltd. for: