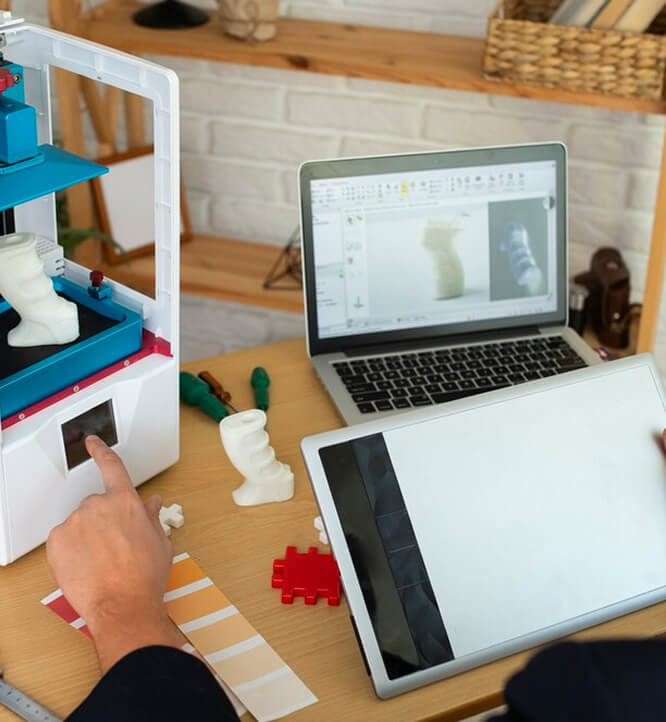

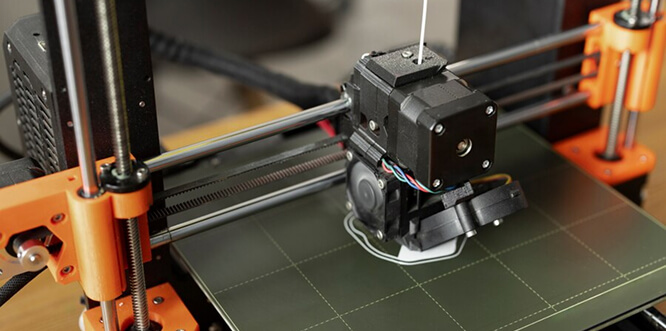

3D printing (3DP), also known as additive manufacturing, is a rapid prototyping technology that uses digital model files as a basis to construct objects by layer-by-layer printing using adhesive materials such as powdered metals or plastics.

3D printers employ standard inkjet printing technology to create each part layer by layer by depositing liquid binders on thin powder layers, forming cross-sectional data to ultimately create a three-dimensional solid model. Samples produced by this technology match the color of the actual product, allowing the model samples to convey a wealth of information.

The application of 3D printing technology is extremely wide-ranging, including but not limited to industrial manufacturing, cultural creativity and digital entertainment, aerospace and defense, biomedical, consumer goods, architectural engineering, and education, among many other fields. It is used not only for prototyping and mold making but also for cultural and artistic creation, jewelry production, aerospace components, manufacturing of artificial bones and teeth for biomedical purposes, as well as architectural models and wind tunnel testing.

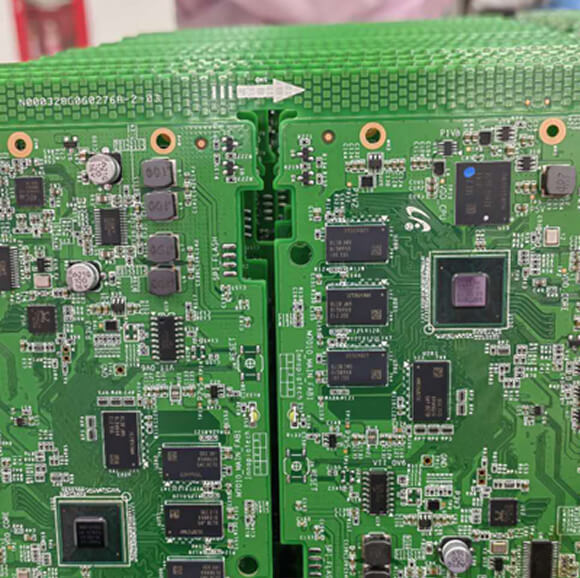

We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

3D printing enables the production of complex geometries and structures with high degrees of freedom. Compared to traditional manufacturing methods, it allows for easier customization of products to meet individualized needs.

3D printing is a rapid prototyping technology that can create physical models or product samples in a short amount of time. It eliminates the need for manufacturing tools and equipment required in traditional methods, speeding up the product development and production process.

3D printing manufactures on-demand, using only the necessary materials, reducing waste and resource consumption. Additionally, material costs can be lowered by optimizing designs to reduce product weight.

3D printing technology provides designers, engineers, and creative individuals with greater innovation space. They can use 3D printing to manufacture complex structures and components, exploring new design concepts and manufacturing methods.

3D printing technology allows for personalized customization according to specific needs. Whether it’s creating medical supports for individual body parts or producing customized spare parts for specific mechanical components, precise fitting can be achieved. Additionally, 3D printing can be used for part repair and replacement.

Traditional manufacturing methods often incur high costs for small-batch or personalized (such as custom-made) production. With 3D printing technology, small-batch customization production can be achieved while reducing production tool and labor costs, thereby lowering production costs.

We're pleased to be welcoming customers to join us.