Turnkey contract manufacturing is the process by which a company outsources its production to a third-party organization, entrusting the contract manufacturer with full responsibility for the product—from design, procurement, and production to assembly, testing, and final delivery. The client only needs to provide product specifications or design requirements without being involved in the manufacturing details.

Many small businesses, startups, and even large corporations choose to work with contract manufacturers because it is significantly more cost-effective than handling production in-house. Contract manufacturers possess the necessary skills, experience, and infrastructure to produce products for other companies. By focusing on optimizing production, reducing costs, and managing the complexities of a fully operational factory, they allow outsourcing companies to concentrate on marketing and selling their products.

We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

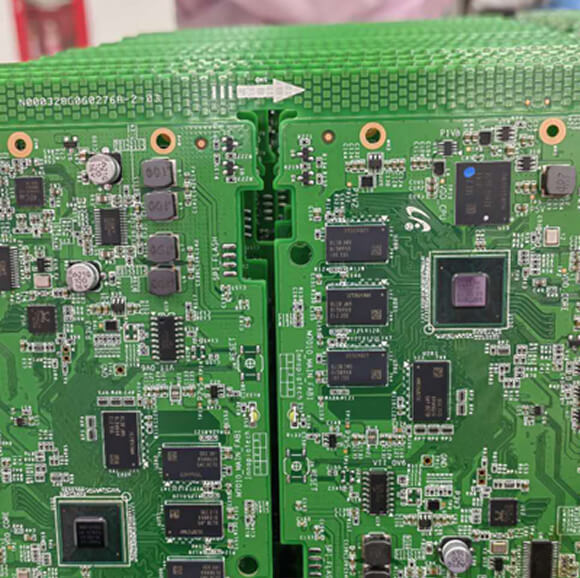

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

The manufacturer works with the customer to complete the product design, ensure that it meets the functional and market requirements, and optimize the design to reduce costs, improve quality and speed up production.

After the design is completed, the manufacturer makes a prototype for testing, collects feedback and makes improvements in preparation for formal production.

After the prototype is tested, the manufacturer purchases the required raw materials and parts from reliable suppliers to ensure material quality and control costs.

Electronic manufacturing requires an efficient and accurate supply chain management capability to ensure that raw material procurement, inventory management and product delivery can be completed in a timely and accurate manner.

The product manufacturing and assembly are the responsibility of the manufacturer, and the customer is not directly involved. The manufacturer ensures that it is completed according to the schedule and specifications..

During the production process, the manufacturer implements strict quality control to ensure that the product is defect-free and meets the requirements.

Finally, the product is packaged according to customer requirements and shipped by suitable means to ensure timely delivery.

We're pleased to be welcoming customers to join us.