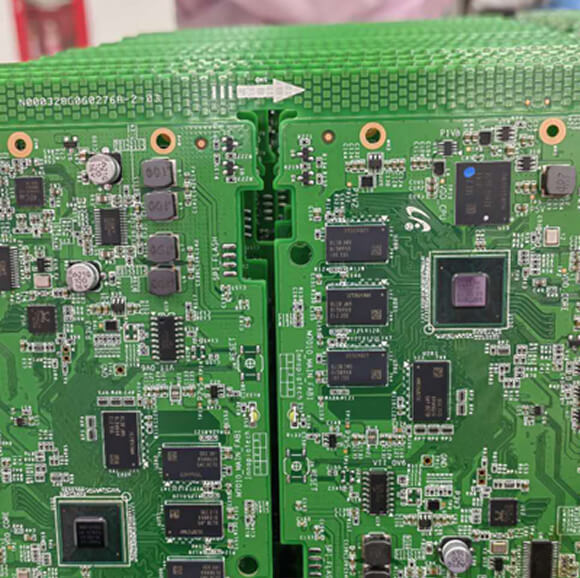

In short, the PCB prototype provides opportunities for the final pre -production analysis of PCB. Using the prototype, you can check the design and the function of the final prototype. It allows you to perform necessary experiments to obtain the most efficient PCB version.

Leadsintec provide quick-turn prototype, low-volume and production PCB assembly with surface-mount (SMT), through-hole (THT) and mix components. We offer turn-key (just send us the Gerber and BOM files), consignment (you supply all parts) and various components purchase options to help you reduce cost and wait time.

Our quick-turn prototyping service can assemble your boards within 24 hours. We can handle small quantity as well as volume productions. All our services are at a very competitive price and with 100% satisfaction guarantee.

We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

You can use prototyping for any type of testing during production. From environmental testing to quality assurance testing, PCB prototyping is your first choice.

You can also use prototyping when dealing with complex designs involving various components. In addition, complex structures with advanced circuitry can be frustrating if errors occur, and prototype PCBs can help you prevent such events from occurring.

If you need a visual representation of the design, you can use a prototype PCB even if it does not yet have functionality. By doing so, you don’t have to spend money on standard production PCBs.

Allows testing and refining layouts during the initial development phase.

Can be used to create non-functional models for presentation or review purposes...

Reduces waste by avoiding full production runs for untested designs..

We're pleased to be welcoming customers to join us.