We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

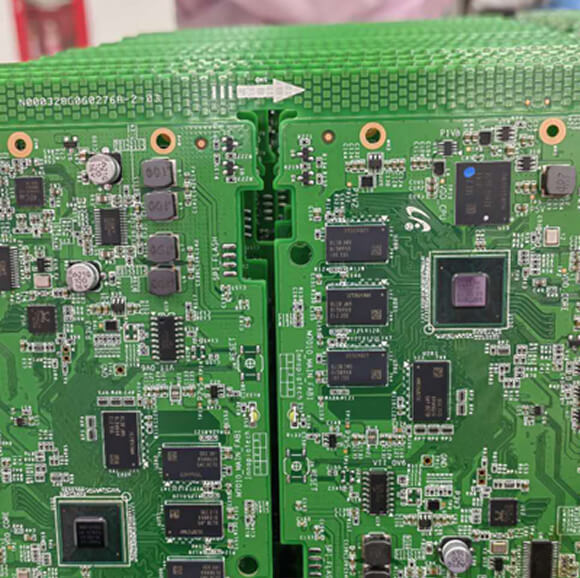

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

ODM PCB is usually designed based on existing technology platforms and modules, so it can greatly shorten the product research and development cycle, help customers push the product to the market faster, seize the opportunity and meet market demand.

ODM customized board card can be customized according to the specific needs of customers to meet specific application scenarios and requirements. This means that customers can obtain a solution that fully matches its needs without compromising or adapting to general products.

Since the ODM customized board card is designed based on the existing platform, the cost and time input of R & D cost and time are relatively low. In addition, ODM manufacturers usually have their own supply chain and production line, which can benefit from the economic benefits of scale, reduce costs and provide competitive pricing.

ODM manufacturers usually have rich technical expertise and experience, especially in specific fields or industries. They can provide comprehensive technical support from hardware design to software development to ensure that the product meets high standards in terms of function, performance and reliability, and has the ability of large -scale production to ensure that the product has high quality and reliability.

In summary, choosing ODM PCB can help enterprises improve efficiency and reduce costs in terms of product development, manufacturing and marketing, while gaining better competitive advantages.

We're pleased to be welcoming customers to join us.

Leadsintec provides professional ODM PCB solutions, offering complete one-stop OEM & ODM printed circuit board design, development, and manufacturing services for global brands, startups, and industrial clients. From concept and PCB design to prototyping, mass production, and final assembly, we help businesses turn ideas into market-ready electronic products faster and more efficiently.

With advanced R&D capabilities, intelligent manufacturing systems, and strict quality control, we deliver high-performance ODM PCB solutions with competitive factory pricing and reliable global delivery.

As a trusted ODM PCB solutions provider, Leadsintec supports customers throughout the entire product development lifecycle, including:

Our turnkey ODM PCB services enable faster product launches, reduced development risk, and lower production costs.

Strong design and engineering expertise is the foundation of our ODM PCB solutions.

Our engineering-driven approach ensures stable performance, optimized cost, and high manufacturability.

Leadsintec operates advanced fabrication and SMT assembly lines to deliver complete ODM PCB manufacturing solutions.

We provide fully integrated ODM PCB manufacturing and assembly services, ensuring quality consistency, shorter lead times, and cost control.

Our standardized ODM workflow ensures efficient, transparent, and reliable product development:

This process allows us to deliver stable, scalable, and market-ready ODM PCB solutions.

Quality excellence is at the core of our ODM PCB solutions.

Every ODM project undergoes multiple quality checkpoints to ensure consistent performance and long-term reliability.

We deliver tailored ODM PCB solutions for a wide range of industries:

Our multidisciplinary experience enables us to handle complex technical challenges and demanding performance requirements.

We help customers reduce development costs, shorten time-to-market, and achieve scalable production success.

Whether you're developing a new electronic product or upgrading an existing design, Leadsintec provides complete ODM PCB solutions that cover design, engineering, manufacturing, assembly, and testing.

We transform your ideas into high-quality, reliable, and cost-effective electronic products.