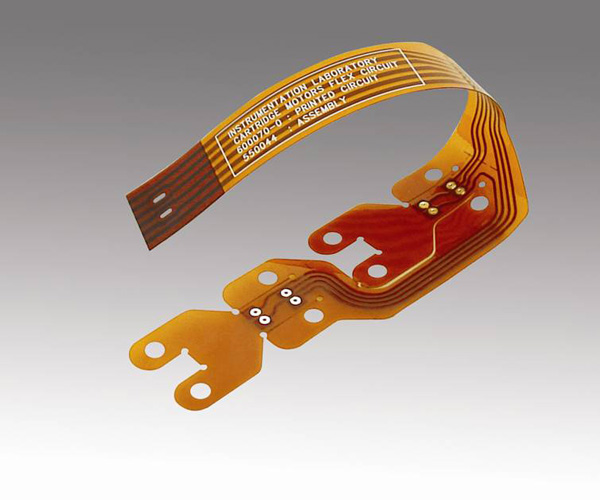

As electronic devices become more compact, lightweight, and functionally complex, traditional rigid circuit boards face limitations in design flexibility. Flexible PCBs (FPCs) are made from flexible base materials like polyimide, allowing circuits to bend, twist, and fold into various shapes. This adaptability enables the integration of electronics into compact, curved, or moving structures without compromising performance or reliability.

Flexible PCBs offer advantages such as reduced weight, space savings, and improved durability in dynamic environments. They are widely used in mobile phones, wearable devices, medical instruments, automotive systems, and aerospace applications. With high wiring density, excellent heat dissipation, and resistance to vibration and movement, flexible PCBs have become essential in next-generation electronic designs where space and flexibility are critical.

Flexible PCBs, also known as flex circuits, are engineered to bend, twist, and fold without losing functionality. Made from flexible insulating materials like polyimide, they allow electronic components to be arranged in tight or irregular spaces. Unlike rigid boards, flexible PCBs offer space efficiency, reduced weight, and enhanced durability in dynamic environments. Their unique properties make them ideal for wearable devices, medical tools, consumer electronics, and automotive systems where compactness and movement are essential. As demand for sleek, portable, and high-performance electronics grows, flexible PCB technology continues to drive innovation in product design.

Number of manufacturing layers: 1-48 layers

Number of SMT lines: 8 high-speed SMT mating lines

SMT daily production capacity: More than 50 million points

Inspection equipment: X-RAY tester, first piece tester, AOI automatic optical tester, ICT tester, BGA rework station

Mounting speed: CHIP component mounting speed (optimal conditions) 0.036S/chip

Minimum package: 0201, accuracy up to +0.04mm

Minimum device accuracy: PLCC, QFP, BGA, CSP and other devices can be pasted, pin spacing up to +0.04mm

18 years of pcb manufacturing experience Authoritative manufacturing team

Adoption of advanced technology and manufacturing equipment Perfect production system Fast turnaround

Mature ISO9001/IATF16949 quality management system. Perfect ERP and MaS order management system.

Professional cost control engineers Cooperation with many raw material companies.

Free DFM inspection of PCB files and BOMs. PCB engineering evaluation and advice.

Specialized in medical, automotive, consumer electronics, new energy pcb. Serving global enterprises

Flexible PCB, also known as a flexible circuit, is an defleeter PCB made of polytamide or polyester film as a substrate. It has significant advantages such as high production efficiency, high wiring density, light weight, thin thickness, foldable bending, three -dimensional wiring, etc., which is more in line with the requirements of the intelligent, portable, and lightness trend of the downstream electronics industry. Flexible PCB can be widely used in aerospace, military, mobile communication, laptop computers, computer peripherals, PDA, digital cameras and other fields or products.

1. Flexibility: Flexible PCB can be bent freely and folded to achieve the integration of component assembly and wiring, high flexibility.

2. Light and flat: Flexible PCB thin and flat, making the equipment structure layout more compact and reasonable, reduce the volume of the product, reduce weight, and facilitate carriers.

3. Strong security: The wire of the flexible PCB adopts the overall connection. The height of various parameters can reduce the error problem when the wire is connected and reduce the occurrence of faults.

4. High -reliability: The wiring of the plane of flexible PCB can reduce switching interconnection, facilitate circuit design, reduce assembly work, improve the reliability of the entire system, and facilitate fault detection.

5. Design flexibility: inductance, capacitance, characteristic impedance, etc. will affect the transmission of the product. The flexible circuit board design is controllable and the electrical performance is excellent. It can be designed as a controllable high -power parameter with transmission line characteristics.

6. It has heat dissipation, weldability, and easy -to -load: there are diverse substrate materials, and different substrates can be used according to different requirements.

7. Adapt to harsh environments: Flexible PCB can be made of various corrosion, waterproof, shock -proof, and moisture -proof materials.

8. Better thermal management: Flexible PCB is made of polytide, which has excellent thermal stability and can withstand extremely high heat.

| Flexible PCB Feature | LST technology Flexible PCB technical specification |

| Materials | FR4, Tg=135150170180210, cem-3, cem-1, aluminum substrate, PTFE, Rogers, Nelco |

| Layer count | Up to 10 layers, |

| Technology highlights | Reliable and cost effective solution for 3D interconnexion with HDI stack-up to 2 step (N+2) option. Dynamic application with multiple bendings. |

| Materials | PEN and PET raw material (only for SS). Polyimide raw material (SS to ML6). Adhesive or adhesiveless with ED or RA copper. Stiffener (FR4 / PI / Al) |

| Base Copper Thickness | From 1/2 Oz base to 2 Oz |

| Minimum track & spacing | 0.075mm / 0.075mm, Advanced 0,060mm / 0,065mm |

| Surface finishes available | OSP, ENIG, ENEPIG |

| Minimum mechanical drill | 0.15mm |

| Minimal thickness | 0,2mm |

| Maxmimum dimensions | 425x590mm. |

We're pleased to be welcoming customers to join us.

Shenzhen Leadsintec Group is a trusted Flexible PCB Supplier and Custom Flexible PCB Manufacturer delivering high-quality bendable circuit boards for today’s advanced electronic devices. Our flexible PCBs are engineered to perform in tight spaces, curved areas, and dynamic environments—while maintaining strong electrical reliability.

We support industries where traditional rigid boards are not suitable, including smartphones, medical devices, wearables, industrial equipment, automotive systems, aerospace, and IoT components.

As a professional Flexible PCB supplier, we design and manufacture flexible circuits that:

Our flex PCBs are ideal for smartphones, implants, automotive sensors, communication devices, and portable equipment where durability and flexibility matter most.

Shenzhen Leadsintec Group is a reputable Custom Flexible PCB Manufacturer offering full-service PCB design, engineering, layout, and production.

We work closely with R&D teams, engineers, and product designers to create flexible circuits tailored to your project—whether prototyping, small batches, or high-volume orders.

Our specialists help you choose the correct materials, copper thickness, polyimide layers, surface finish, and protective coating based on your product’s environment and performance needs.

As an expert Flexible PCB supplier, we provide:

Flexible PCBs offer benefits that rigid boards cannot match, including:

1. Space-saving design

They can bend, fold, and wrap around internal components—perfect for compact devices.

2. Weight reduction

Essential for aerospace, medical implants, portable electronics, and mobility devices.

3. Higher reliability

Fewer solder joints and interconnections reduce failure points.

4. Superior vibration and shock resistance

Ideal for automotive, industrial, and military applications.

5. Reduced assembly complexity

No need for bulky cables or connectors between rigid boards.

Our flexible PCBs include:

Every flexible circuit passes strict quality control to ensure long-term mechanical and electrical stability.

Partnering with us ensures:

Whether you need a small trial order or large-scale production, our team ensures smooth, consistent, and high-precision manufacturing.

Shenzhen Leadsintec Group is committed to becoming your long-term Flexible PCB Supplier and Custom Flexible PCB Manufacturer, offering tailor-made flex PCB solutions to support your product’s innovation and performance.

1. What industries use flexible PCBs?

Flexible PCBs are used in medical devices, smartphones, automotive electronics, wearables, aerospace, industrial automation, and IoT devices.

2. What materials are used in flexible PCB manufacturing?

Most FPCs use polyimide due to its heat resistance, flexibility, and durability.

3. What is the difference between flexible PCBs and rigid-flex PCBs?

Flexible PCBs are fully bendable, while rigid-flex combines flexible layers with rigid sections for structural support.

4. How long does it take to manufacture flexible PCBs?

Prototypes can take 3–7 days, while mass production varies depending on layer count and complexity.