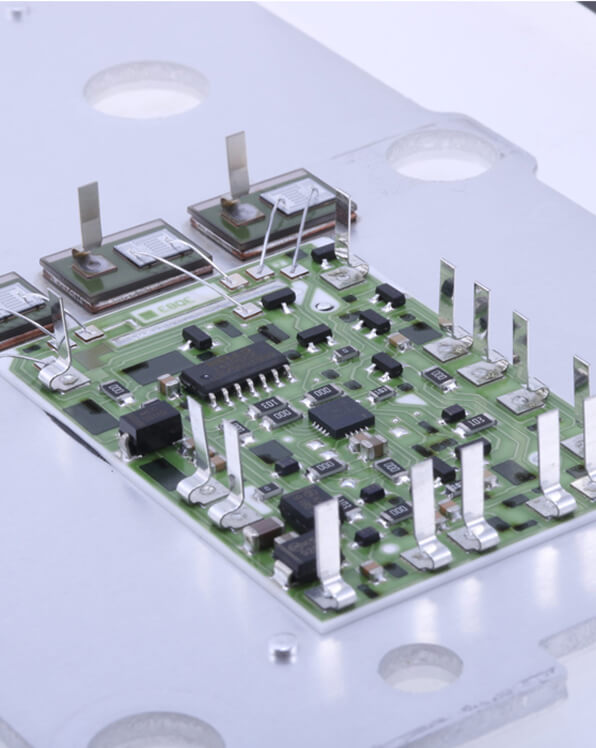

As the electronic packaging technology gradually develops towards miniaturization, high density, multi -function, and high reliability direction, the power density of the electronic system increases, and the heat dissipation problem becomes more and more serious. For electronic devices, the device is usually reduced by 30%to 50%every 10 ° C increased by 10 ° C. Therefore, the use of appropriate packaging materials and processes and improvement of device heat dissipation ability has become a technical bottleneck to develop electronic devices.

Among them, the selection of substrate materials is a key link, which directly affects the cost, performance and reliability of the device. The commonly used substrate materials mainly include four categories: plastic substrates, metal substrates, ceramic substrates and composite substrates. At present, although ceramic substrates are not dominant, due to their good thermal conductivity, heat resistance, insulation, low thermal expansion coefficients and costs, the application of electronic packaging, especially power electronic devices, is becoming more and more extensive.

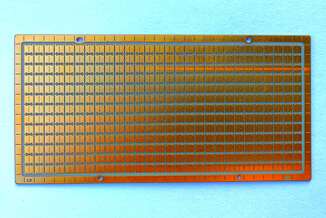

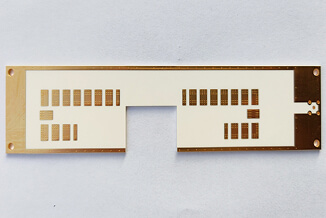

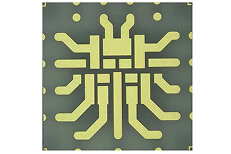

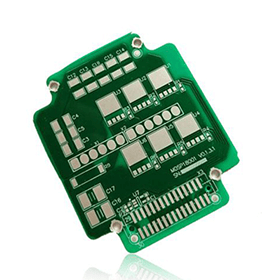

Ceramic substrate refers to a special craft board that is directly kept on copper foil directly to alumina (Al2O3) or aluminum nitride (Aln) ceramic substrate or other ceramic substrates at high temperature. The ultra -thin composite substrates made have excellent electrical insulation performance, high thermal conductivity characteristics, excellent soft welding and high attachment strength, and can be carved out of various graphics like PCB boards. ability. Therefore, ceramic PCB board has become the basic material of high -power power electronic circuit structure technology and interconnection technology.

Unlike traditional FR-4, ceramic materials have good high-frequency performance and electrical performance, have high thermal conductivity, chemical stability, excellent thermal stability, and other properties that organic substrates do not have. It is a new ideal packaging material for the generation of large-scale integrated circuits and power electronic modules.

Main advantages:

Alumina is the most commonly used substrate material in ceramic substrates, because compared with most other oxide ceramics, it has high strength and chemical stability in terms of mechanical, thermal science and electrical properties. technology. Manufacturing and different shapes. The percentage of alumina (Al2O3) can be divided into: 75 porcelain, 96 porcelain, and 99.5 porcelain. The content of alumina is different, and its electrical properties are hardly affected, but their mechanical properties and thermal guidance are very different. There are many glass with low purity substrates, and the surface roughness is large. The higher the purity of the substrate, the smoother, the dense, and the lower the dielectric loss, but the higher the price.

It has a higher thermal conductivity than metal aluminum, which requires high thermal guidance applications. After the temperature exceeds 300 ° C, the temperature drops rapidly, but its toxicity limits its own development.

Aluminum nitride ceramics are ceramics with aluminum nitride powder as the main crystal phase. Compared with alumina ceramic substrates, it has higher insulation resistance, higher insulation resistance and lower dielectric constant. Its thermal conductivity is 7-10 times that of AL2O3, and its thermal expansion coefficient (CTE) is similar to the silicon wafer, which is essential for high-power semiconductor chips. In the production process, ALN’s thermal guidance rate is greatly affected by the content of remnant oxygen impurities, and reducing oxygen content can significantly increase thermal guidance. At present, the heating coefficient of the process production level exceeds 170W/(m · k) is no longer a problem.

HTCC

LTCC

DBC

DPC

Traditional ceramic substrate manufacturing methods can be divided into four types: HTCC, LTCC, DBC, and DPC.

The HTCC (high temperature co-fired) preparation method requires a temperature above 1300°C, but due to the choice of the electrode, the preparation cost is quite expensive.

The LTCC (low temperature co-firing) requires a calcination process of about 850°C, but circuit precision is poor, and the thermal conductivity is low.

The DBC requires formingan alloy between the copper foil and the ceramic, and the calcination temperature needs to be strictly controlled within the temperature range of 1065-1085°C. Because the DBC requires the thickness of the copper foil, generally, it cannot be less than 150-300 microns. Therefore, the wire width to depth ratio of such ceramic circuit boards is limited.

The preparation methods of DPC include vacuum coating, wet coating, exposure and development, etching, and other process links, so the price of its products is relatively high. In addition, in terms of shape processing, DPC 1800 ceramic fiber board plates need to be laser cut. Traditional drilling and milling machines and punching machines cannot accurately process them, so the bonding force and line width are more precise.

We're pleased to be welcoming customers to join us.

Ceramic PCB fabrication is the ideal choice for organizations seeking a reliable and fire-resistant circuit board. Shenzhen Leadsintec Group is a pioneer in the production of ceramic PCBs that operate in high temperatures and other extreme conditions.

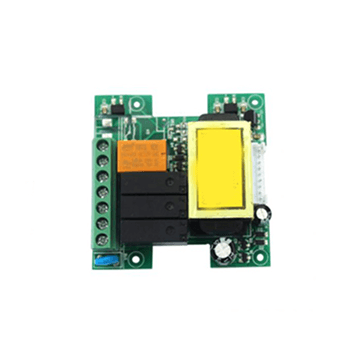

These high-technology circuit boards are made with non-fiberglass but with ceramic materials that offer excellent thermal and electrical properties. Businesses across various sectors utilize ceramic PCBs in high-power devices, LED lighting, and harsh environments where non-ceramic boards often fail.

There is no other technology that offers higher reliability in harsh environments than Ceramic Substrate PCB technology. The given ceramic base material can be heated to 1000 °C without any changes in electrical performance.

This qualifies the ceramic boards as ideal for power electronics, RF applications, and military devices. In comparison to standard PCBs, ceramic ones are less prone to expansion or contraction under hot and cold conditions, providing assurance of reliability in use.

We also produce ceramic substrate PCBs with micron-level accuracy, which is required in critical situations.

We maintain a dimensional tolerance of +/-0.025 mm consistently across all features, even in high-stakes performance situations.

Variability is eliminated, ensuring repeatability in production through advanced CNC machining and automatic inspection systems.

In our controlled atmosphere furnaces, we maintain a temperature within ±2 °C during firing, ensuring consistent material properties.

By outsourcing ceramic PCB fabrication to our plant, you will save money because you will not have to invest in costly equipment. By collaborating with us, companies can save between 30% and 50% of the production cost compared to developing in-house.

We have a staff of committed project managers who would coordinate directly with your engineering departments and guarantee smooth communication during production.

Supply chain management involves obtaining raw materials, managing stock, and delivering what suits your production schedules. Our vendor relations enable us to get competitive prices on ceramic substrates and copper materials, which we then pass on to our customers.

We offer a competitive pricing policy, and we have the flexibility of quantity (from a single prototype order to large production). We will find a cost-effective solution for any business.

Our supply chain offers worldwide shipping, utilizing advanced ceramic technology, to startups and large firms, delivering anywhere unconditionally.

Shenzhen Leadsintec Group provides high-precision and consistent ceramic PCB fabrication services. Our high-end manufacturing process ensures the quality and performance of PCBs that meet industry standards. Our reliable solutions are available when you require prototypes or hundreds of production units.

We collaborate closely with B2B customers worldwide to support them throughout their projects, from design to final delivery. Our ceramic material is thoroughly tested and of the highest quality. Our modern processes ensure performance and reliability.