Mold is a tool for molding items. It is mainly through the change of the physical state of the forming materials to achieve the processing of the shape of the item. The molds generally include two parts: motion and fixed molds (or convex molds and concave molds). Remove the parts when separated, and make the ingredient into the mold -shaped cavity when it is closed. The mold is a precision tool, with complicated shapes, and bearing the bloating power of the blank material. It has high requirements for structural strength, stiffness, surface hardness, surface roughness, and processing accuracy.

Moldings are widely used in industrial production in the methods of injection molding, blowing, extrusion, die casting or forging molding, smelting, stamping and other methods to obtain various molds and tools for the required products. It is widely used in the forming of crushing, molding, coldness, squeezing, powder metallurgy compression, pressure casting, as well as compression or injection molding of engineering plastics, rubber, ceramics and other products. Depending on the processing objects, molds are generally divided into plastic molds and metal molds.

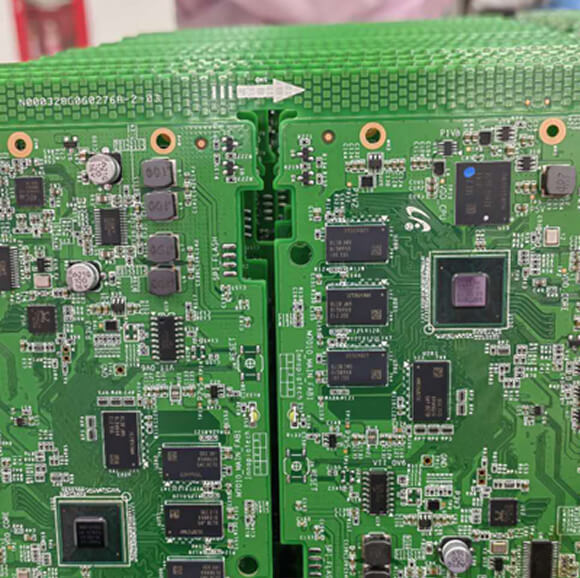

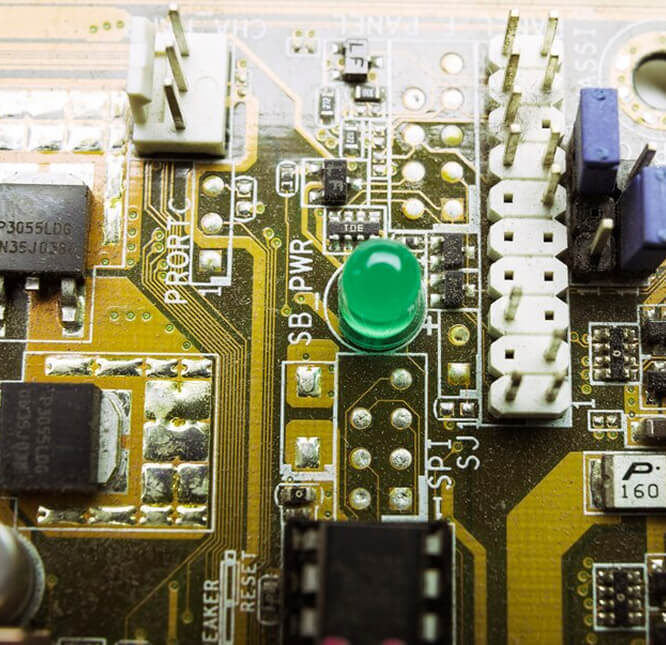

We provide almost the entire product cycle, from electronic design, prototype production, and PCB assembly, to cable and wiring beam assembly, complete system integration, and product testing. We provide comprehensive electronic manufacturing services, with excellent quality and fast turnaround times. This allows us to meet the needs of customers’ various projects.

We can provide customers with PCB one -stop service, including PCB design, PCB manufacturing, PCB assembly, PCB test, electronic component procurement.

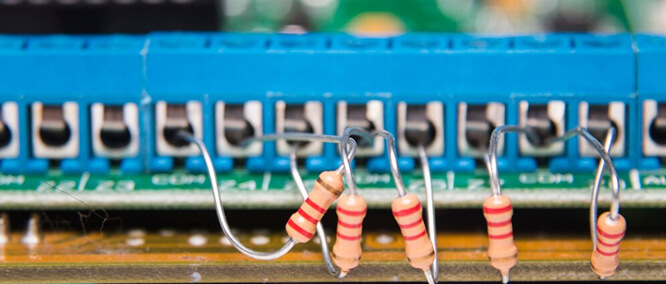

Any top EMS supplier has assembled cables as one of its electronic services fields. It involves the production, engineering design and testing of cable components, mechanical components and wiring beams. It can also include panel assembly and wiring.

EMS suppliers should provide electromechanical assembly services, mainly manufacturing plastic, steel or aluminum boxes. Other services related to electromechanical assembly include packaging, functional testing and 3-D modeling.

LST provides complete electrical and mechanical box assembly services, which can be customized according to the customer’s requirements to save them time and money.

Our professional engineers are well versed in electronic design with extensive experience in PCB design & layout, power electronics design, embedded hardware design, and more!

We do various tests, including functional tests. Because of any errors, this is a very important step in the process, X -ray testing, etc. to ensure that each product can meet your expectations.

Different plastic raw materials have different processing temperature, too high or too low temperature will affect the processing performance of plastic and product quality. Therefore, according to the characteristics of raw materials and process requirements, strict control of processing temperature.

You can also use prototyping when dealing with complex designs involving various components. In addition, complex structures with advanced circuitry can be frustrating if errors occur, and prototype PCBs can help you prevent such events from occurring.

The injection molding time is the time it takes for the plastic to cool and cure in the mold. The length of this time will also affect product quality and productivity. According to the specific conditions of the product and mold, need to reasonably select the cooling time and molding time.

The processing environment of injection molding will also affect the quality and production efficiency of the product, such as temperature, humidity, cleanliness, etc.. Need to ensure that the processing environment is stable and meet the process requirements.

The skills and experience of the operator will also affect the quality and efficiency of injection molding. Need to choose experienced and skilled injection molding machine operators, and regular training and skills upgrading.

In the process of injection molding, quality inspection is needed, such as the appearance of the plastic, size, performance and so on. This can detect and solve quality problems in time, improve production efficiency and product quality

We're pleased to be welcoming customers to join us.